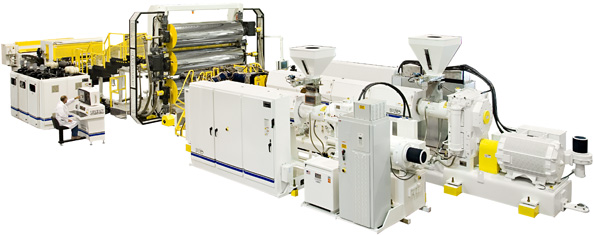

TRIDENT® Model 7000 (7.0"/175mm) Water Cooled Extruder with 700HP AC Drive TRIDENT® Model 4500 (4.5"/115mm) Water Cooled Extruder with 300HP AC Drive; REVOLUTION® Model V1203636 Vertical Sheet System with vertical roll stand positioning system and full length access catwalks flanking both sides of the conveyor.Bath Surrounds/Appliance Liners

PTi designs and manufactures a wide range of systems used to produce technical parts including those for bath and appliance applications.These lines can range in size depending upon the application up to 120"(3050mm) in width. Various lamination options are available including primarynip for cosmetic sheet effects and masking stations for protective film application. |

Sheet Takeoff system with high flow roll temperature control circuits, Dual Catwalks, Telescoping conveyor and triple positions. |

PROCESS SUMMARY

|

Resins |

PS & ABS |

|---|---|

|

Gauge |

0.110 - 0.325" (2.79 - 8.26 mm) |

|

Width |

100" (2,540 mm) |

|

Rate |

5000+ lbs/hr (2285+ kg/hr) |

FEATURES INCLUDE

|

Fully integrated TITAN® Plus Control System |

|---|

|

AUTORAMP™ line control and coordination Pivoting main extruder base for ease of maintenance Thread-up leader winder Spare chrome roll temperature control circuit |

|

Vertical roll stand height positioning system |

|

Primary nip and protective masking lamination stations |

|

And more! |

|

|

Processing Technologies International, LLC, 2655 White Oak Circle, Aurora IL 60502 © 2022 Processing Technologies International, LLC P: 630.585.5800 F: 630.585.5855