|

| |

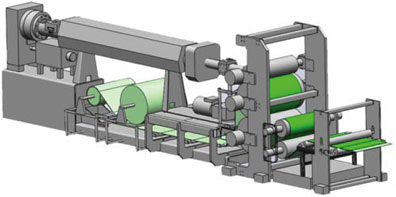

TRIDENT® Model 6500 (6.5"/165mm) Water Cooled Extruder with 600HP AC Drive; TRIDENT® Model 5000 (5.0"/127mm) Water Cooled Extruder with 300HP AC Drive; Compact Hybrid REVOLUTION® Model V601836 Three Roll Sheet Take-Off SystemLaminationPTi offers various designs for performing lamination functions for sheet production. These are categorized as primary nip for hot sheet lamination or an alternative downstream location for warm or cold sheet lamination. The substrate can be applied to either the top or bottom side of the sheet depending upon the specific requirement. Masking protective films are another option for downstream laminating of sheet to protect the surface of the sheet against cosmetic defects caused by product handling though various equipment stages.

|

Dual station unwind units are |

Special lamination unwind capability allows substrate to be applied to the bottom side of the hot sheet at the primary nip point.