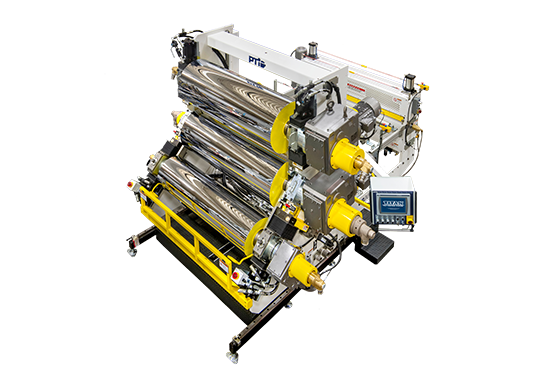

eG-SERIES® ConfigurableScalable Systems That Evolve With Changing Demands PTi introduces an engineered hybrid to its robust line of G-SERIES® Configurable Roll Stands, the eG-SERIES®, comprised of many of the same design features found within the G-SERIES® product line. However, given its unique arrangement, the eG-SERIES® represents PTi's most compact roll stand variant presently being offered, focusing on a system that offers the smallest footprint possible, benefitting those with limited production floor space. The same G-SERIES® philosophy applies to the eG-SERIES®, placing emphasis on achieving high quality sheet by maintaining accurate cooling temperatures throughout the extrusion process, while incorporating design features that simplify operations. G-SERIES® Panted Technology Included in the eG-SERIES®

Roll Configurations and Precision The unique benefits of the eG-SERIES® Roll Stands are currently being offered in J-stack or vertical down configurations, with small to medium sized rolls ranging from 36 thru 66 inch widths and roll diameters from 12 thru 30 inches. Obtaining exact sheet thickness and a proper cooling is made possible via specifically engineered design of features that adjust positioning and temperature accordingly. Hydraulic and linear bearing supported roll actuation, with motorized gap positioning, provide ease in obtaining sheet thickness requirements. High precision spherical tapered roller bearings support chrome rolls for 0.0003 - 0.0005; (3 - 5 ten thousandths) Total Indicator Reading (TIR) runout in the stand. In addition, open loop temperature control modules, for precise roll temperature set point maintenance, allow for dedicated heat and direct inject cooling for each chrome roll zone, with a maximum 200GPM on middle chrome roll and max 130GPM on primary and secondary nip chrome rolls.

The eG-SERIES®; Roll Stand can be tailored to include the following equipment: Roll Skew, Servo Motorized Gap, Safety Roll Lock-outs, and eAntiSTAT™ Coater with one set of rubber covered squeegee rolls. PTi's multi-patented roll stands offer the most advanced technologies available in the industry, both as standard and optional features, with an emphasis on ease of operation and safety. To learn more about these roll stands please contact PTi.

|

Catwalk for ease of operator access

Vertical nip height adjustment

Transfer roll coater for top and/or bottom side coating

eG-Series®; Roll Stand Features

To achieve a compact footprint, featureshave been streamlined within the eG-SERIES®, this includes:

- Consolidated routings for water, hydraulic, air, and electrical utilities (eliminates the need for rear positioned energy tracks);

- Compact side car for open loop temperature control modules and control cabinet affixed to frame;

- Stationary pendant, TITAN®;PLC touch screen control interface, at a fixed height; and

- Super compact conveyor arrangement.