PTi, Aurora, IL and FARREL POMINI, Ansonia, CT form a Strategic Business Alliance (SBA) to produce compounding sheet extrusion systems integrating FARREL POMINI's mixing and PTi's sheeting technologies. This combination eliminates pre-compounding of resins such as mineral fillers, colorants, impact modifiers, clarifiers, etc. which can now be mixed and directly extruded into sheet in a continuous process. DTS™ Compounding brings together FARREL POMINI and PTi as technology leaders offering best-in-class sheet extrusion equipment.

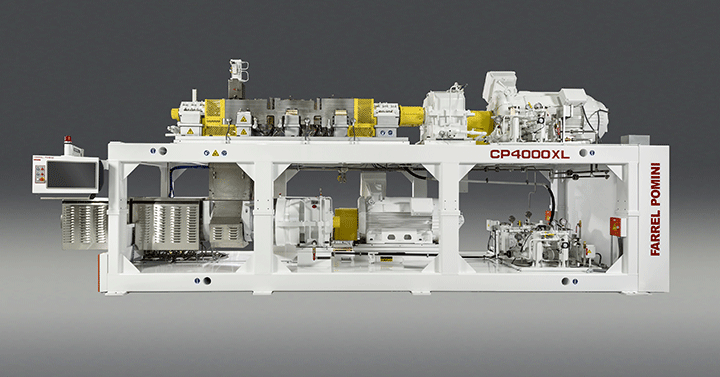

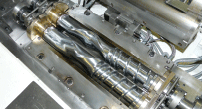

FARREL POMINI's CP SERIES II™ Compact Processor Model CP4000

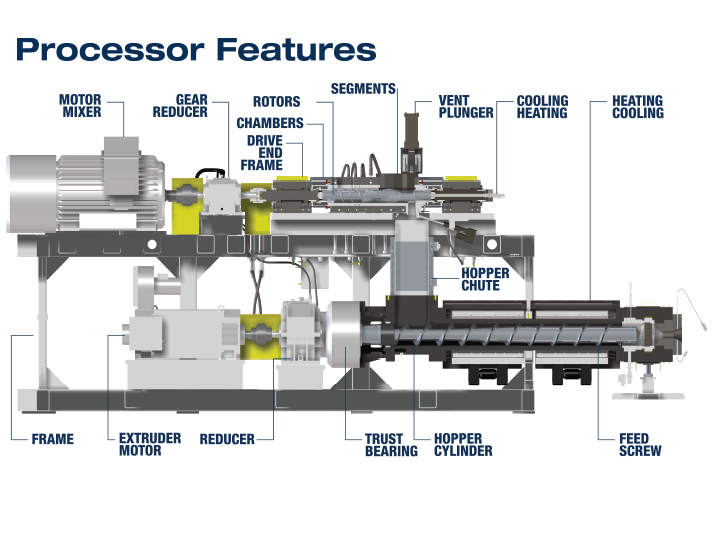

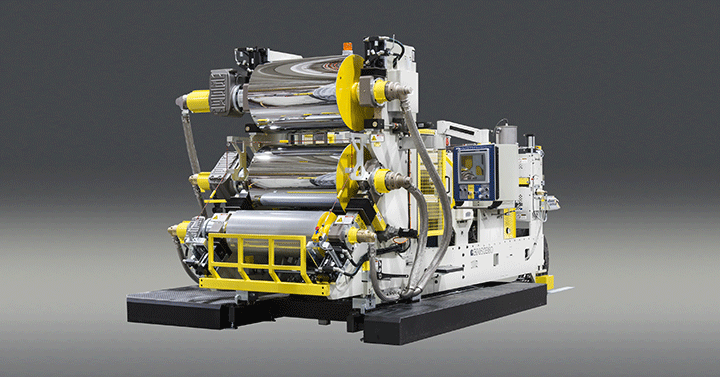

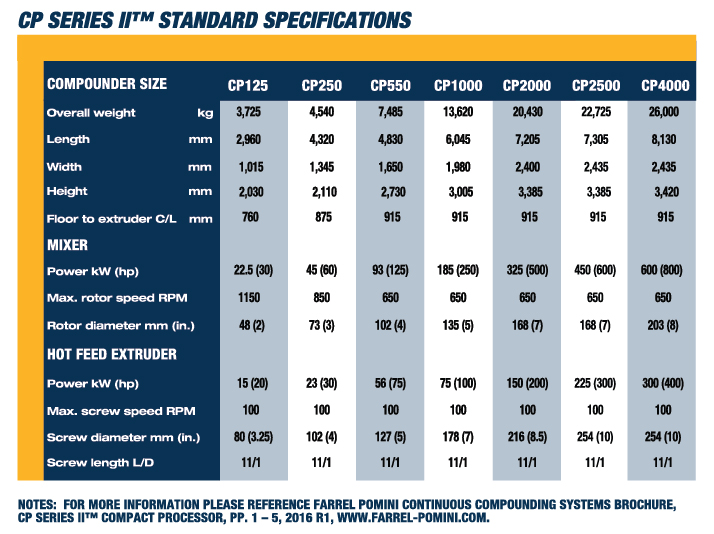

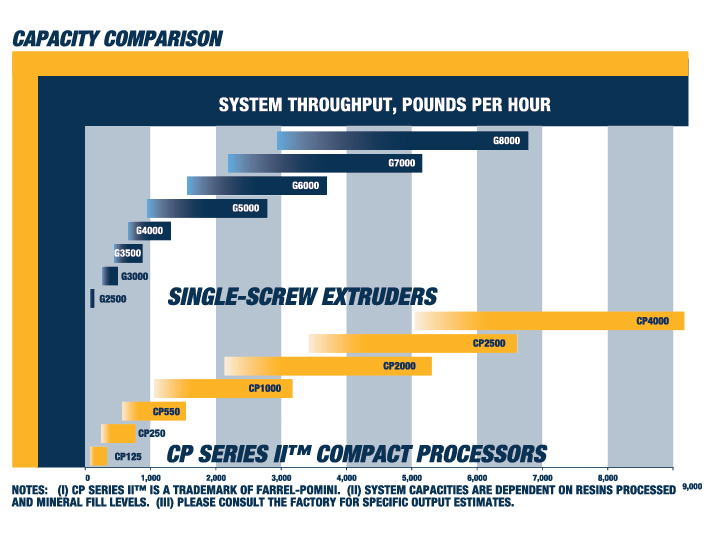

DTS™ Compounding brings together both FARREL POMINI and PTi as technology leaders in their respective markets and as a result, offer best-in-class sheet extrusion equipment. FARREL POMINI's compounder, the CP Series II™ Compact Processor, is designed specifically for top quality dispersion of highly filled, highly pigmented materials, capable of processing a wide range of polymer applications with high output rates. This technology compliments PTi's G-SERIES® Roll Stands' abilities to process a wide range of sheet applications, including thin to heavy gauge, low to high melt strength resins, and high output production.

PTi's G-SERIES® J-stack Configurable Roll Stand Model 661830

What does DTS™ Compounding mean to the industry? The benefits include cost savings, process efficiencies and enhanced control of compounded materials for companies requiring considerable percentages of mineral fillers in their extruded sheet. DTS™ Compounding can be configured inline directly feeding a thermoformer or as a roll stock system producing wound rolls of sheet offline. This highly unique offering will introduce a first-of-its-kind processing into strategic packaging, automotive and industrial sheet markets

Key Advantages:

- RAPID ROI OVER OTHER TECHNOLOGIES (LESS THAN A YEAR)!.

- COMPACT MACHINE FOOTPRINT

- LONG COMPONENT LIFE BETWEEN REBUILDS/ REPLACEMENT 3+ YEARS AT 70+% MINERAL LOADING

- LOW ENERGY CONSUMPTION/HIGH EFFICIENCY MIXING

- MULTI-RESIN SOLUTION THAT PERMITS MINERAL LOADINGS UP TO 70%!

- SINGLE POINT FEED OPENING FOR EASE OF FORMULATION CONTROL AND HOUSEKEEPING CONTAINMENT

Machine Specs:

Throughput:

DTS™ Compounding technology produces sheet with high mineral loading (up to 70+%)!

Unique rotor designs permit low shear compounding while using a single point feed entrance.