Super G Multi-Nip™ Model SGMN J601818/512 J-Stack Roll Stand features energy tracks for opening accessibility, mechanical device for ease of thread-up, roll skew for thin gauge processing(pat. pend.), Patented bearing toggle for multi-nip performance, servo-gap control for precise operation, patented linear traverse & nip height positioning and more!

Roll Stands - Super G Multi-Nip™

PTi is a leading manufacturer of highly engineered sheet extrusion systems. This article illustrates and describes the benefits of PTi's newly introduced all-nipping roll stand for cooling and polishing sheet. The major benefits of this design are as follows:

- Multi-patented technology assures all rolls are properly nipped for optimal performance;

- High capacity thermal ability provides uniform core temperature ideal for Form, Fill & Seal applications;

- Multi-roll arrangement yields ultra-low sheet orientation (i.e.; stress-free production);

- Compact configuration minimizes system footprint; and

- High quality sheet aesthetics result from the all-nipping rolls.

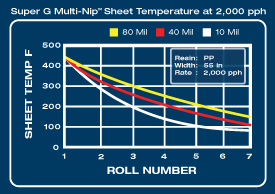

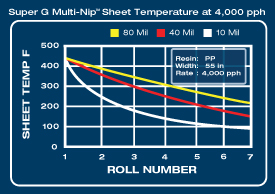

The charts listed above show the average sheet temperature as the sheet passes through the unique roll stand. The analyses examined 80, 40 and 10 mil sheet thicknesses at production rates of 2,000, 3,000 and 4,000 lbs/hr for unfilled PP resin at 55 inch sheet widths. In each case the data reveals the achievement of a rapid cooling rate while maintaining balanced average web temperatures. This results in the production of a high quality 'stress free' sheet ideal for many demanding sheet applications including Form, Fill & Seal. Comparative analyses were performed using much larger roll stand configurations as a benchmark. In each case the Super G Multi-Nip™ out performed these benchmark cases.

The charts listed above show the average sheet temperature as the sheet passes through the unique roll stand. The analyses examined 80, 40 and 10 mil sheet thicknesses at production rates of 2,000, 3,000 and 4,000 lbs/hr for unfilled PP resin at 55 inch sheet widths. In each case the data reveals the achievement of a rapid cooling rate while maintaining balanced average web temperatures. This results in the production of a high quality 'stress free' sheet ideal for many demanding sheet applications including Form, Fill & Seal. Comparative analyses were performed using much larger roll stand configurations as a benchmark. In each case the Super G Multi-Nip™ out performed these benchmark cases.

Energy tracks assures open accessibility

Mechnical device for ease of thread-up

Patented bearing toggle for multi-nip performance

Roll skew for thin gauge processing (pat. pend.)

Servo-gap control for precise operation

Patented linear traverse & nip height positioning