Featured News - Current News - Archived News - News Categories

PTi Announces NPE Show Line: Thin-Gauge 'Dryer-Less' PET/PLA Sheet System

Company to Showcase Unique Thin-Gauge Sheet Extrusion Line at NPE 2015

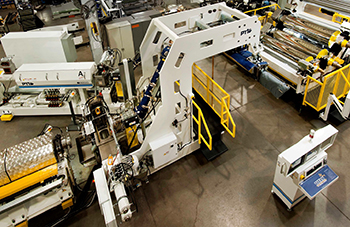

Processing Technologies International (PTi), a leading global manufacturer of high-performance sheet extrusion machinery, has announced its showcase system at NPE 2015: The International Plastics Showcase, March 23-27 at the Orange County Convention Center in Orlando (Booth #W4182).

The NPE Line is an 85mm/52D HVTSE®

extruder with a GCH661824 horizontal roll stand and is capable of producing 57"

wide PET/PLA sheet at thicknesses down to 6 mil or PP sheet at thicknesses down

to 11 mil. This system, available subject to prior sale, operates at 2,300 lb/hr or a total

of 18 million lb of annual PET production. It will be the fourth installation

in the last six months, and in addition to the units sold from the 2011 launch, will

represent a theoretical installed capacity of 390 million lb of annual North

American PET production.

The NPE Line is an 85mm/52D HVTSE®

extruder with a GCH661824 horizontal roll stand and is capable of producing 57"

wide PET/PLA sheet at thicknesses down to 6 mil or PP sheet at thicknesses down

to 11 mil. This system, available subject to prior sale, operates at 2,300 lb/hr or a total

of 18 million lb of annual PET production. It will be the fourth installation

in the last six months, and in addition to the units sold from the 2011 launch, will

represent a theoretical installed capacity of 390 million lb of annual North

American PET production.

"We initially thought that the energy savings and process simplification of the dryerless technology would be the selling points, however, we've quickly seen that the equipment's resin versatility has been the primary driver," said Matt Banach, PTi's vice president of sales and marketing.

Systems ranging from 85 to 170mm are capable of processing PET at rates ranging from 2,300 lb per hour (1,045 kg/hr) to 5,500 lb/hr (2,500 kg/hr), and convert a variety of resins including post-consumer and industrial PET/PLA, PP, HDPE, HIPS and more. The energy-efficient process relies on High-Vacuum Twin-Screw Extruder (HVTSE®) technology, which allows virgin or recycled PET to be processed without the need for raw material drying and crystallizing. The "dryerless" sheet extrusion system is an eco-conscious manufacturing solution which delivers major energy and cost savings, according to Banach. It is a significant reduction in the carbon footprint of virgin and recycled PET sheet production.

In terms of sustainability advantages, the HVTSE® process provides a reduction of about 80-85 kWh/1000 lbs in energy consumption versus conventional PET processing. "This savings equates to more than 31.6 gigawatt hours of annual power consumption when factored across our 390 million pounds of theoretical installed HVTSE® PET capacity base," said Sushant Jain, senior scientist at PTi. "The resultant energy savings could mean a reduction in CO2 gas emissions of more than 23 million pounds per year from fossil-fuel burning power plants."

The NPE line unit boasts several novel features including PTi's new G- Series® configurable roll stand. The GCH661824 three-roll horizontal system permits greater flexibility and significantly reduced downtime for system modifications. "The new G-Series® Horizontal facilitates the production of some of the thinnest PET and PP thermoformed sheet in the market," according to Banach. "The roll stand was developed in response to market demand for high-quality, thin-gauge sheet for the production of lightweight packaging."

Other key features include PTi's Titan® Plus Integrated PLC control system, multi-resin capability, rapid resin changeover, and advanced safety features.

PTi has a demonstration line at its Aurora, Ill. headquarters which is available to sheet manufacturers for product evaluation using their own virgin and recycled materials. Banach noted that customers have the ability to run production-scale trials instead of scaling up from a small lab-scale pilot line that can often result in inaccurate estimations and unfavorable results.