Featured News - Current News - Archived News - News Categories

PTi's Develops New Die Splitting Cart

by Kathleen Flannery

uCAMS™ Delivers Safety and Simplicity to the Die Cleaning, Maintenance and Assembly Process

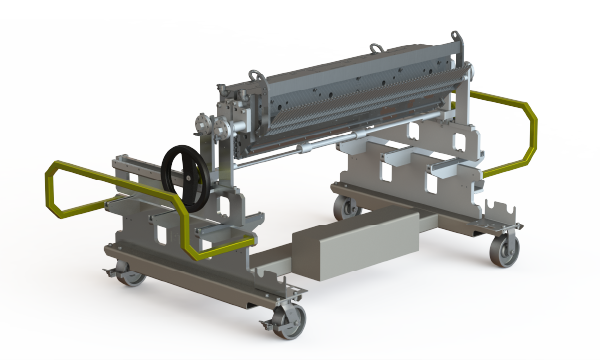

July 21, 2021— Processing Technologies International, LLC (PTi), Aurora, IL announces the development and release of a die splitting cart, the uCAMS™ (Universal Cleaning Assembly and Maintenance System). Extrusion die cleaning and maintenance are necessary for high-quality sheet production, so finding ways to expedite the process, while improving upon efficiency and safety, ultimately means better quality sheet with less downtime. Understanding this goal, PTi's put significant thought into the engineering and design of this unique die splitting cart, taking into account the need for flexibility, ease, and operator safety in regards to maintenance and upkeep of an extrusion die.

The uCAMS™ is foundational for any offline die maintenance program and is available in three configurations for the cleaning, inspection or repairs of single, dual or triple-manifold dies. The heavy-duty frame construction on casters provides mobility and accessibility so that maintenance can be performed in an environment and at a height that is adequate and safe for the operator.

In comparison to other die splitting carts on the market, PTi's uCAMS™ offers unique features that simplify the maintenance process. The first is its ability to accommodate variable die widths (1000mm to 2000mm (39" - 79") through the integration of adjustable trunnion supports. This versatility is a tremendous benefit for plastic processors working with varied die widths, as it eliminates the need for multiple, width-specific carts or trunnions. Secondly, the uCAMS™ is equipped with a single hand-wheel mechanism which requires only one person to perform the die splitting procedure. Upon manual rotation of the wheel, and within a matter of seconds, the die is separated into respective components which are then capable of turning 360 degrees for even greater access to the die surfaces. Lastly, for those instituting SMED protocols for LEAN production, the onboard tool box further enhances workflow efficiency by having all the necessary equipment and tools readily available.