Featured News - Current News - Archived News - News Categories

PTi is Granted U.S. Patent for New Height Adjustment Device for G-Series® Roll Stand

by Lukasz Jagiello

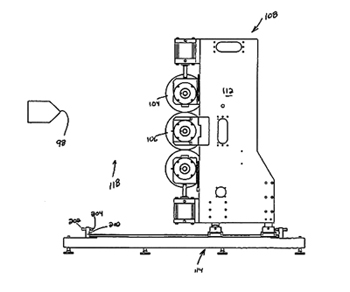

AURORA, Ill., September 18, 2012 - Processing Technologies International (PTi), a leading global manufacturer of high-performance sheet extrusion machinery, has been awarded a U.S. patent for its new ratchet-activated height adjustment device which raises and lowers the cooling and polishing rolls relative to the sheet die exit for optimal sheet performance. The height positioning mechanism is simpler, less time-consuming, and more cost effective than competitive manual and motorized methods.

"This new invention is built into the roll stand and delivers a distinct advantage, offering processors reduced cost and higher quality sheet materials," said James Johnson, PTi's Senior Vice President-Technical Consultant. This is the third patent (No. 8,240,180 B2) that PTi has received for its G Series® linear bearing mounted roll stand. Previously awarded patents include US 8,021,140 for the design of the G-Series linear bearing mounted roll stand and US 8,152,509 for the new manual roll gap adjustment device.

Typical sheet lines are set up with the die exit directly in-line with the primary roll nipping point. This is acceptable for many materials however, with low-viscosity polymers such as polyethylene terephthalate (PET) there is a tendency for the sheet to droop on the lower roll before nipping. This creates a skinning effect which results in undesirable stresses in the extruded sheet. Repositioning of the roll nip so it is lower than the die exit effectively minimizes the droop and significantly improves sheet quality. This repositioning is accomplished through adjusting the height of the rolls.

As a standard feature on its G-Series roll stand, PTi has incorporated a jack screw arrangement with ratchet operating mechanism for uniformly raising or lowering the stand on both sides within +/- 1.0 inch. This cost-effective solution gives the operator the ability to make use of this adjustment while in full operation. An indicator provides the exact positioning of the rolls at all times.

The ratchet-activated height adjustment device offers numerous benefits over conventional methods. For example, a common way to adjust roll positions is to use casters with a jack screw and manually adjust each side of the roll stand independently. This is a time-consuming operation and is best done when the line is not in operation. More sophisticated sheet manufacturing lines use a more costly motorized jack screw or cam to raise or lower both sides of the roll stand up or down in unison.

The patented G-Series roll stand has cooling rolls that are mounted on a linear motion guide track. Instead of moving the entire frame, only the cooling rolls move when access to the die network is required. Movement on the linear motion guide track is extremely precise and repeatable, ensuring exact tracking and precise sheet alignment.

Initial installation of the G-Series roll stand takes only approximately 16 work hours. Leveling of the frame does not require track installation but instead uses leveling pads which are pinned to the floor. Another inherent advantage of the G-Series design is the utility line for air, water, and electrical connections which are located beneath the frame deck plate. This placement yields unimpeded access to all key components for serviceability and maintenance.

The G-Series roll stand requires less space and fits in tighter confines because the frame does not move when the cooling rolls traverse back and forth. The roll stand is a key feature on PTi's Globaline® Series of sheet extrusion systems and is also sold separately.

About Processing Technologies International LLC (PTi) Processing Technologies International LLC, based in Aurora, Ill., is a leading global manufacturer of high-performance sheet extrusion machinery, serving more than 22 countries. Established in 1988, PTi produces and services single-screw extrusion equipment for many end-use markets including packaging, construction, automotive, lawn and garden, office products, signage and displays, and appliances. PTi's extrusion systems are engineered to exacting standards and offer an exceptional range of design features which result in superior equipment performance. More information is available by calling (630) 585-5800 or visit www.ptiextruders.com.