GENESIS™ Program—Features and Auxiliaries*

*Genesis Inventory as of date 05.05.2023. Inventory is subject to change.

CONVENTIONAL SINGLE SCREW EXTRUDERS

☐ G3000 (3.0” 32D 75 HP Air Cooled)

☐ G3500 (3.5” 32D 150 HP Air Cooled)

☐ G5000 (5.0” 32D 300 HP Air Cooled)

☐ G6000 (6.0” 32D 500 HP Air Cooled) Qty 2

HIGH SPEED EXTRUDERS

☐ SGHS3000 (75mm 36D 150 HP Air Cooled)

☐ SGHS3000 (75mm 36D up to 500 HP Air Cooled); Qty 2

☐ SGHS3500 (90mm 36D up to 600 HP Air Cooled); Qty 2

TWIN SCREW EXTRUDERS (Dryerless Multi-Resin)

☐ SGTSE-90mm (90mm 50D 430 HP Oil Cooled)

☐ HVTSE-70 (70mm 52D 300 HP Oil Cooled)

☐ HVTSE-85; QTY 2 (85mm 52D 400 HP Oil Cooled)

☐ HVTSE-105 (105mm 52D 500 HP Oil Cooled)

MATERIAL HANDLING

☐ Maintech 5 Component Material Transfer to feed twin screws

☐ Doteco 5 Component Blender LIW feeding system for twin screws

SCREEN CHANGERS

☐ CSC-148 Maag Dual Bolt 2 Cavity Screen Changer

☐ CSC-176 Maag Dual Bolt 2 Cavity Screen Changer

☐ CSC-125/BF-4F Maag Dual 4 Cavity Bolt Screen Changer w/backflush

☐ K-SWE-125-4K-75/RS (Kreyenborg 4 Cavity Dual Bolt Screen Changer w/backflush)

☐ TSK 5-2 XRS (Trendelkamp 4 Cavity Dual Bolt Screen Changer w/backflush)

GEAR PUMPS

☐ Maag 90-371 GP; Qty 2

☐ Maag 110-716 GP

SHEET DIES AND FEEDBLOCKS

☐ Nordson EDI A/B/A Feedblock; Qty 2

☐ Nordson EDI 42” Die H40

☐ Nordson EDI 42” Die HM100

☐ Nordson EDI 48” Die HM100

☐ Nordson EDI 62” Die HM100; Qty 2

☐ Nordson EDI 70” Die HM100

CHROME ROLL STANDS

☐ eGVD541818 (eG-Series 54” Wide 18” Dia. Vertical Down Stack)

☐ eGJ541818 (eG-Series 54” Wide 18” Dia. J Stack)

☐ eGJ541824; (eG-Series 54” Wide 18-24-24” Dia. J Stack) Qty 2

☐ eGJ541830; (eG-Series 54” Wide 18-30-30 Dia. J Stack) Qty 2

☐ GVD661824 (G-Series 66” Wide 18-24-24 Dia. Vertical Down Stack)

☐ GVD661830 (G-Series 66” Wide 18-30-30 Dia. Vertical Down Stack)

☐ GJ661824 (G-Series 66” Wide 18-24-24 Dia. J Stack)

☐ GJ661830 (G-Series 66” Wide 18-30-30 Dia. J Stack)

☐ GJ721824 (G-Series 72” Wide 18-24-24 Dia. J Stack)

☐ GJ721830 (G-Series 72” Wide 18-30-30 Dia. J Stack)

☐ AUX-6618/2 (2 Roll Auxiliary Cooling Unit, 66” Wide 18-18” Dia.)

☐ AUX-7218/2 (2 Roll Auxiliary Cooling Unit, 72” Wide 18-18” Dia.)

SHEET COATING UNITS

☐ eAntiSTAT54 (eG-Series Antistatic Coater Unit 54” Wide)

☐ AntiSTAT TRC54 (G-Series Transfer Roll Coater 54” Wide)

☐ AntiSTAT TRC66 (G-Series Transfer Roll Coater 66” Wide)

☐ AntiSTAT TRC72 (G-Series Transfer Roll Coater 72” Wide)

PULL ROLL UNITS

☐ PR54 (G-Series Pull Roll Unit 54” Wide 6” Dia. Rubber/Steel), Qty 2

☐ PR66 (G-Series Pull Roll Unit 66” Wide 8” Dia. Rubber/Steel), Qty 2

☐ PR72 (G-Series Pull Roll Unit 72” Wide 8” Dia. Rubber/Steel)

CHROME ROLL COOLING MODULES

☐ 130GPM, DIRECT COOL (Chrome Roll Temp Control Module) Qty 3

☐ 200GPM, DIRECT COOL (Chrome Roll Temp Control Module) Qty 3

☐ 130GPM, w/HTEX (Chrome Roll Temp Control Module Closed Loop) Qty 6

☐ 200GPM, w/HTEX (Chrome Roll Temp Control Module Closed Loop) Qty 5

WINDING EQUIPMENT

☐ A66100 (Sheet Accumulator 66” Wide 100’ Volume) Qty 2

☐ ACW6640/2 (Cantilever Winder 66” Wide Differential 2-up Max.40” Dia. Buildup) Qty 2

☐ A78100 (Sheet Accumulator 78” Wide 100’ Volume)

☐ ASCW7848/2 (Semi-Auto Cantilever Winder 78” Wide Differential 4-up Max. 48” Dia. Buildup)

☐ Helios Slitter Station 3 Blade Rotary with position control

☐ Helios Slitter Station 5 Blade Rotary with position control

CONTROL AUTOMATION

☐ TITAN® PLUS (TITAN Plus Control System)

RECYCLING EQUIPMENT

☐ WRP-35s (Nordson Water Ring Pelletizer)

☐ 6000 Stuffer Ram (Ram Feeder For 6” Extruder) Qty 2

SERVICE AND MAINTENANCE

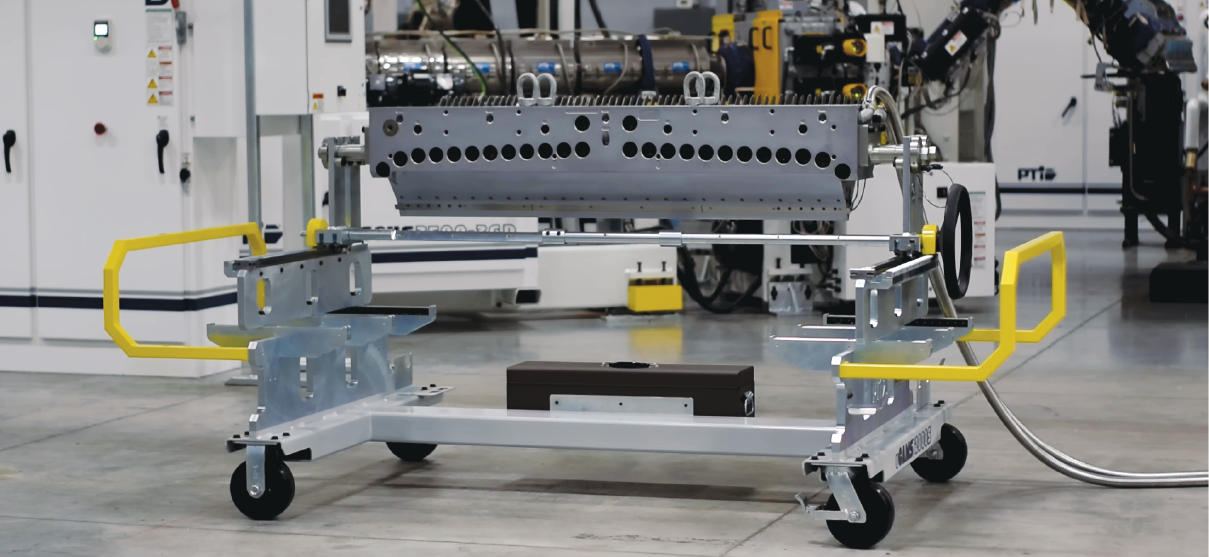

☐ uCAMS-2000S (Die Servicing Station, Widths up to 2000mm)

☐ uCAMS-2000S Plus (Die, Chrome Roll & Feed Screw Service Station) Qty 2

GENESIS™ Program Scope and Configurations:

- Various extruder combinations defined above may be arranged with the roll stands featured herein. However, thruput capacities must be balanced with thermal loading capabilities to assure optimal results are achieved. Check with factory regarding specification compatibilities.

- Many ancillary items are available and too numerous to list, check with factory for specifics.

- If the sheet die desired isn’t featured, a custom die may be ordered while the balance of the system is being completed and installed, loaner dies are also available.

- GENESIS™ Program is a living inventory of standard equipment items listed above. Check with factory for current list and availability of specific items desired.

- All equipment listed above are well appointed with advanced performance features and patented technologies. All details will be identified in the formal proposal describing the desired items. Check with factory for specification details.

- Major equipment items featured herein are available with customer-specified operator handedness. Confirm details with factory.

- All equipment featured herein is painted PTi White RAL 9003. Limited custom paint schemes may be available. Check with factory for specifics.